After steels are tapped (poured) from the electric furnace, they are refined (further processed) in a Ladle Refining Furnace (LRF). This process is used to reduce impurities and adjust the chemical composition of the molten steel.

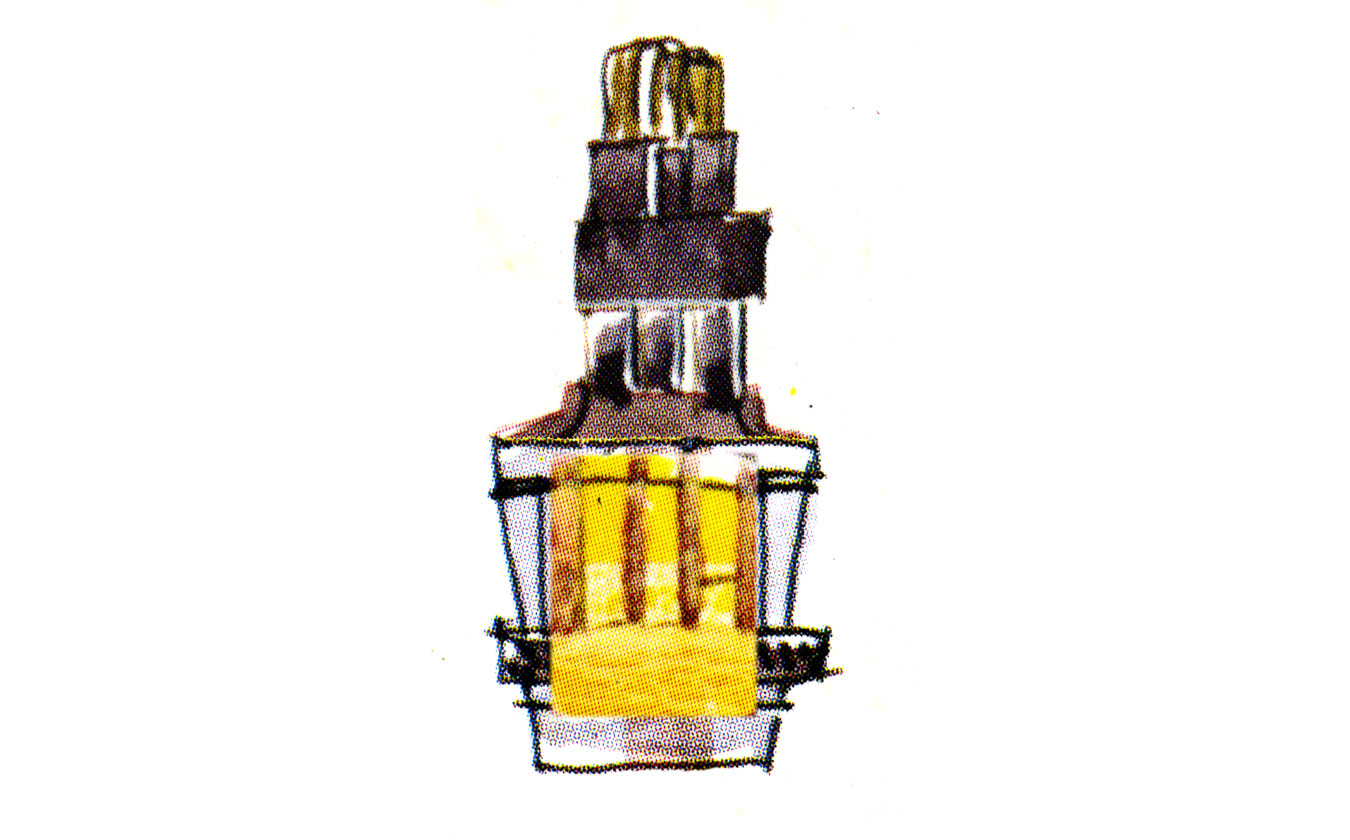

Molten steel is tapped from the Electric Arc Furnace into a ladle, which is moved to the LRF station. There, new slag is added and a roof containing three graphite electrodes is lowered onto the ladle. Argon is injected into the ladle and a stirring motion mixes the steel with the slag. The mixing reduces impurities and alloys are added to meet customers’ specifications.

Once the correct chemical composition and temperature are achieved, the steel is sent on for casting.