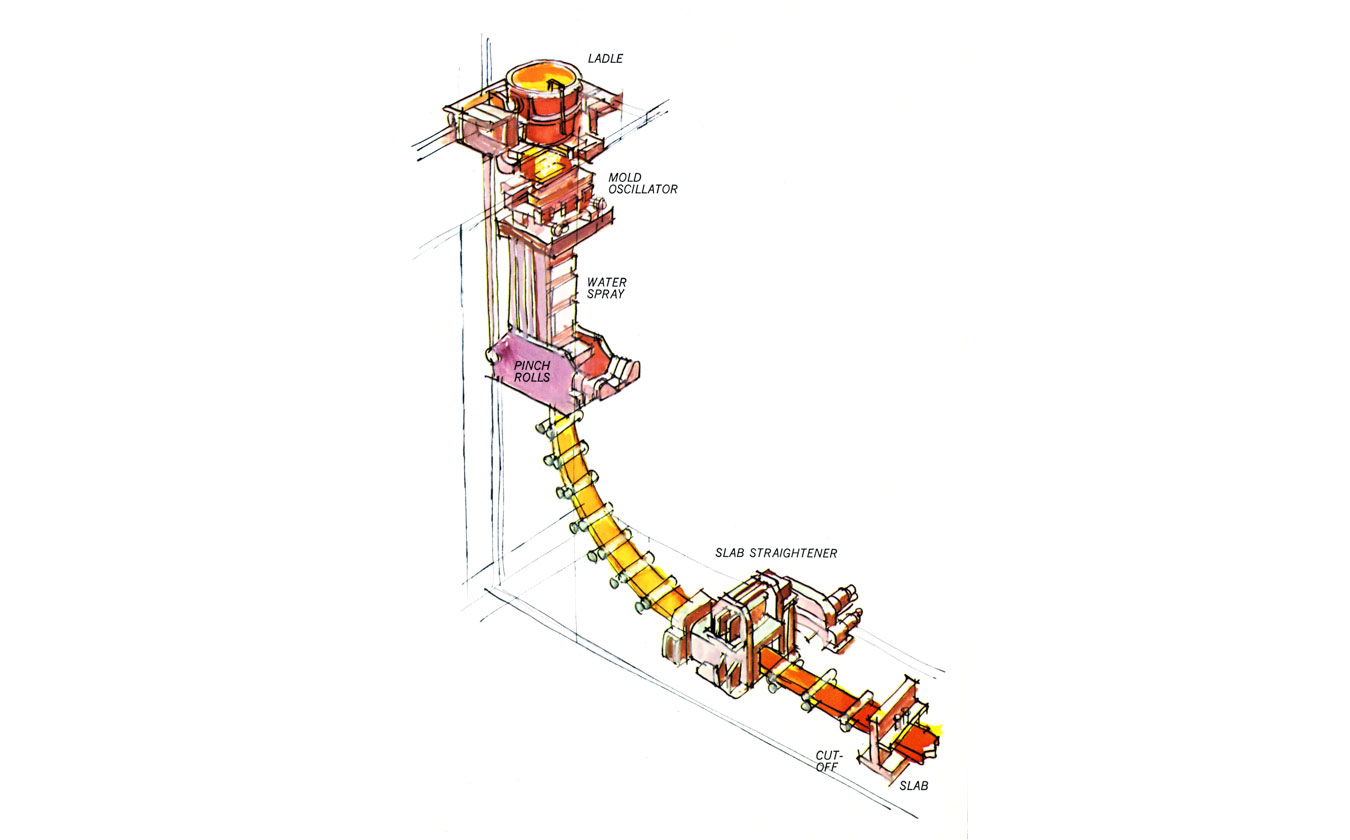

Billets, blooms, or slabs can also be produced directly from molten steel. Liquid steel is poured from a ladle into the caster. As the steel flows slowly through the copper mold, cold water cools the steel, causing it to solidify. A moving torch then cuts the steel into desired lengths. Continuous casting is more efficient than ingot casting.

Lukens Steel Company never used the continuous casting process for steels produced in open hearth furnaces, only for steels produced in electric furnaces.