Liquid steel is poured from a ladle into molds. After the steel cools and

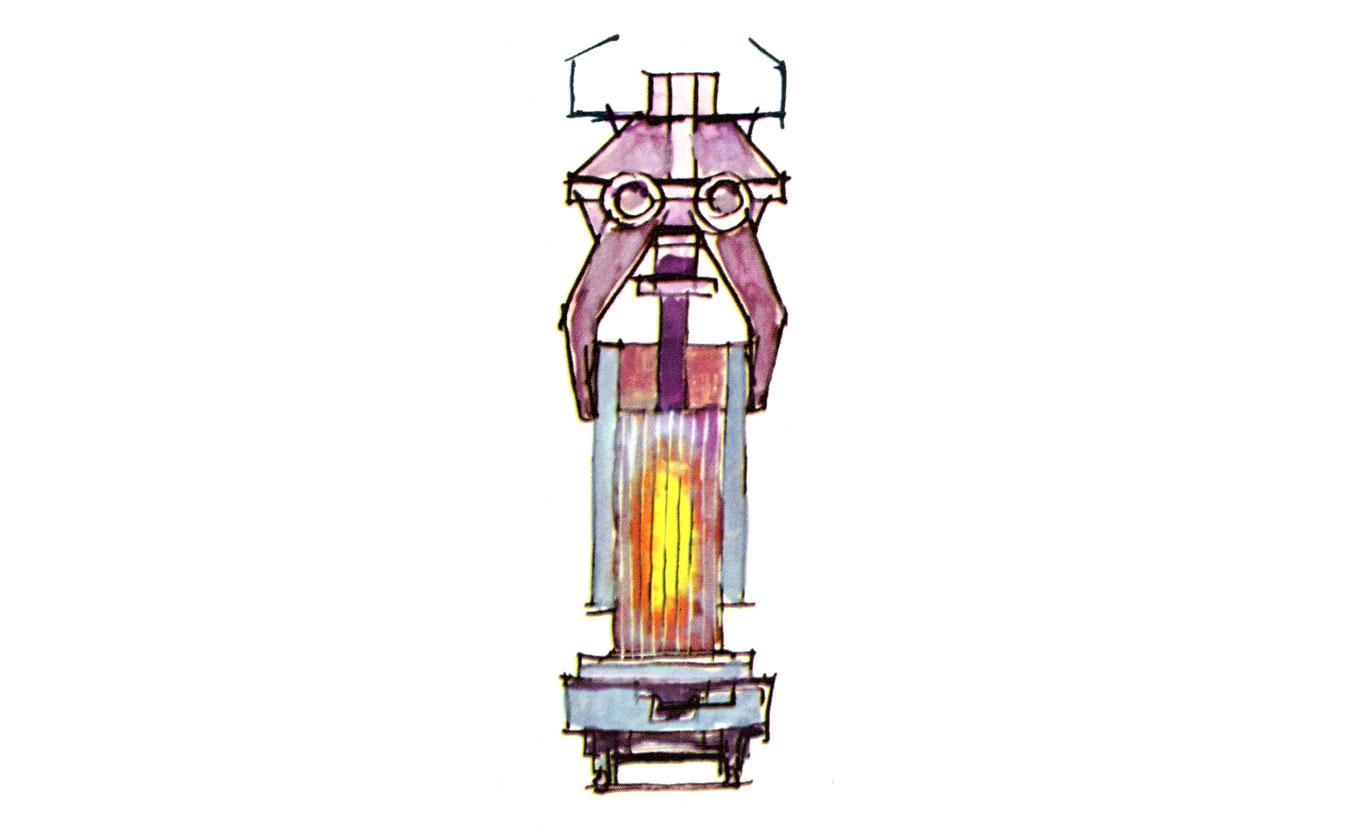

hardens, the mold is lifted off by giant tongs and the ingot is placed

in a heated soaking pit, where it remains until it reaches about 2200ºF. The

heated ingot is taken to a rolling mill, where rollers squeeze the ingot into a longer

and thinner shape, called a billet, bloom, slab, or plate.