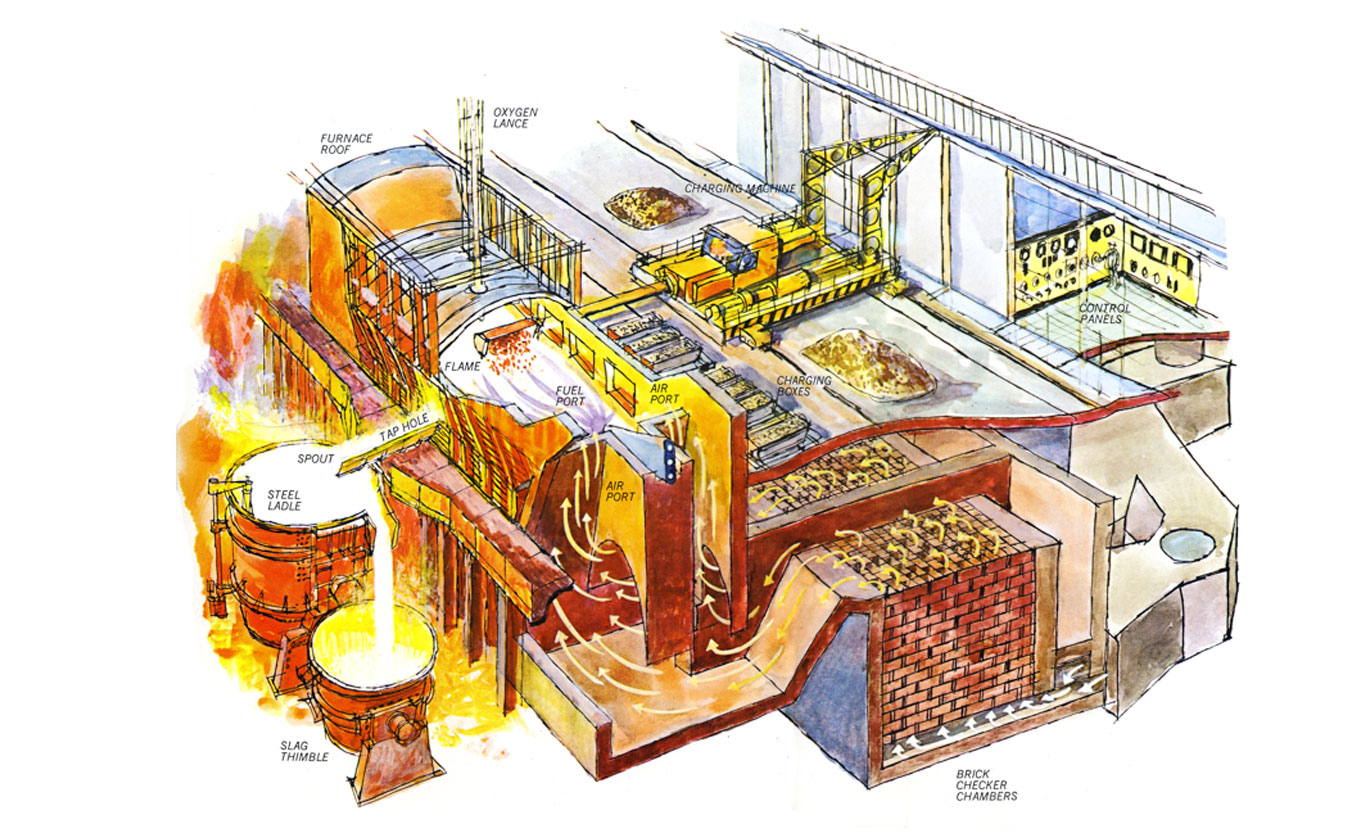

An open hearth furnace has a lining of refractory and a low, arched roof that covers the hearth, which is open directly to flames that melt the charge. This process uses about equal amounts of iron and scrap.

Steel is produced in an open hearth furnace by the following steps:

1. A machine dumps limestone and scrap steel (the charge) into the furnace.

2. After the charge melts, molten or cold iron is added.

3. Heating continues. Carbon from the iron becomes carbon monoxide gas. Impurities are separated and form slag.

4. The remaining product is molten steel, which flows into a large ladle where alloying materials may be added.

Lukens Steel Company used a 100% cold charge because it did not have a source of molten iron. This process was largely phased out in the United States by the 1980s.